Reactor-Ready Pilot Lab Reactor

Replace multiple reactor set-ups with a single, universal pilot scale system – 5 to 35 litres

Why choose Reactor-Ready Pilot?

Replace multiple reactor set-ups with a single, universal pilot scale system with interchangeable vessels that can be swapped in minutes NOT hours. Compatible with AVA Lab Control Software.

Flexible

Range of single jacketed vessels from 5 litres to 35 litres. Range of vacuum jacketed vessels from 5 litres to 10 litres. Choose from two precision ground lids with DN200 vessel flange.

Interchangeable

Rapid vessel exchange with quick-release vessel clamp and wide bore hose couplings. Accepts all leading brands of overhead stirrer and allows easy, tool-free adjustment.

Universal

Compact stainless steel framework accepts all vessel sizes. Vessels have 1.25 to 1 ratio of internal height to diameter to mimic plant scale reactors.

Simple

Self-aligning stirrer coupling engages without the need for tools. Innovative hose manifolds allow easy thermofluid drain down.

Range of single jacketed vessels

from 5 litres to 35 litres

Range of vacuum jacketed vessels

from 5 litres to 10 litres

Process vessels

to mimic larger scale plant or manufacturing vessel geometries

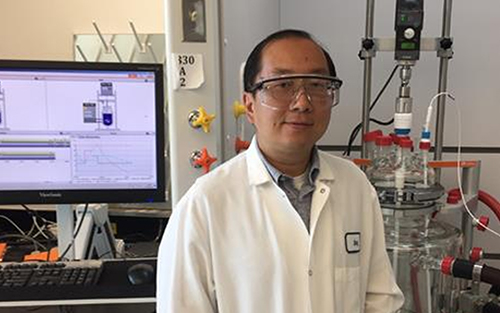

The Radleys Reactor-Ready systems incorporate many clever designs that greatly improve the user experience and AVA Software is a big step forward from the conventional way of manual control and lack of data logging.Dr. Jing Liu, Scientist III, Process Chemistry Department, Dart Neuroscience

Take control

AVA Lab Control Software allows scientists to achieve precise temperature control and accurate process data logging in their jacketed lab reactor experiments, leading to reproducible chemistry and seamless tech transfer. Log and control stirrers, circulators, balances, pumps, temperature sensors and other devices.

Introducing our new 30 & 35 litre vessels

Scale up your chemistry from 5 to 35 litres, in a single framework, using the Reactor-Ready Pilot Lab Reactor.

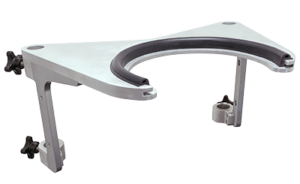

Universal stirrer support

- Compatible with Radleys and other leading brands of overhead stirrer

Simple stirrer alignment

- 6 axis adjustment

- Slide and glide

- Set and lock

Patented stirrer coupling

- Drop in

- No tools

- No fuss

Single Reaction System

- A single reaction system that accepts single jacketed vessels from 5 to 35 litres and vacuum jacketed vessels from 5 to 10 litres

Standard Jacketed vessels

- Single jacketed vessels 5 litres to 35 litres

- Vacuum jacketed vessels 5 litres to 10 litres

- Zero dead space bottom outlets valve

- Ratio 1.25:1.

- Custom vessels in a range of sizes and styles

- In-house manufacturing

- Mimic plant scale geometry

Compact, mobile framework

- Corrosion-resistant stainless steel, anodised aluminium or powder-coated steel

- Option for wheels or feet

Unique vessel clamp

- Self-centering

- Change vessels in minutes

Hose couplings

- Chemical-resistant PEEK

- Quick-release

- Connect in seconds

- 20 mm ID for good heat exchange

Thermofluid manifolds

- Easy connection

- Easy drain down

- Reduces stress on vessel sidearms

A choice of popular PTFE stirrer paddles

- Anchor

- Retreat Curve

- Turbine or Propeller

Automate your chemistry and reap the benefits

AVA lab control software has been designed to simplify your experiments while improving the accuracy of your data and quality of your yields.

Free up lab time with automated logging of temperature, stirring, pH and more.

Evaluate AVA Software for yourself with our free Demo version.

Reactor-Ready Pilot Core System

The Reactor-Ready Pilot Core includes all of the following components:

- Base frame, support rods, vessel clamp, i-beam and stirrer support bosses

- Vessel to manifold insulated hoses with quick-release connections

- Lower inlet manifold with drain

- Upper outlet manifold with vent

Reactor-Ready Pilot Core System

- PTFE Stirrer guide

- Stainless steel stirrer drive coupling

- One aluminium vessel support collar

- FEP flange O-ring and PTFE centering collar

Hoses to connect the Reactor-Ready Pilot framework to your thermoregulator are NOT included. You will require hoses with an M30x1.5 female connection or appropriate adapters. See below for hoses, adapters and suitable thermoregulators.

Pilot Reaction Vessel Features

- Precision engineered borosilicate glass vessels

- Choice of DN200 6 or 7 neck Glass Lids that fit all vessel sizes (custom options available)

- Vessels feature V4 Zero Dead Space Drain Stopcock which prevents over-tightening which can cause glass breakage

Jacketed Vessels

Accepts single jacketed vessels of 5, 10, 15, 20, 30 and 35 litres and vacuum jacketed vessels of 5 and 10 litres

- Single jacketed 5 to 35 litres

- Vacuum jacketed 5 and 10 litres

- Zero dead space drain

- Ratio 1.25 to 1

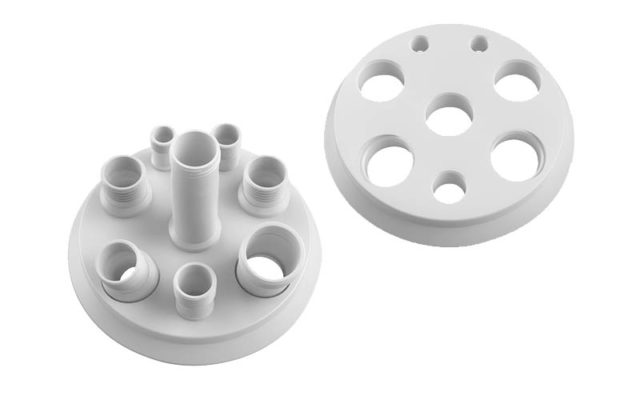

Reactor-Ready Pilot Glass Lids

DN200 Glass Lids fit all Vessel sizes. Choose from two standard configurations with 6 or 7 Rodaviss glass joints or request a custom design.

- DN200 Glass lids fit all vessel sizes:

- DN200 lid with either 6 or 7, Rodaviss conical ground glass joints

- Rodaviss joints are grease free, will not jam and are interchangeable with ordinary 1-in-10 B and A length tapered conical joints

- Rodaviss A length joints are also available

PTFE Vessel Lids

Ideal for use with PAT and test probes

- Removable PTFE sockets and compression fittings allow for maximum flexibility, simply unscrew and change the fitting to suit your set-up.

- More suitable for PAT and test probes than equivalent glass lids.

- Allows for more ports in a smaller space (8 rather than 6 or 7).

- More robust and less likely to break than glass.

- Less dead space at top of vessel.

Polypropylene Drip Trays

- Drip trays are NOT included in the Pilot core and must be ordered separately

- Chemically resistant polypropylene designed to catch any spills and vessel contents in case of breakage

- Available in 7, 22, 45 and 55 litre capacities

- Slide easily onto the Reactor-Ready Pilot base

How to order Reactor-Ready Pilot

- Select the Reactor-Ready Pilot Core

- Choose the lid you require (custom options available)

- Choose the Vessel Kits you need

- Select the overhead stirrer you need

- If you need a thermoregulator, hoses, hose adapters, thermofluid or accessory glassware, then select from the accessory list

- If you need automation add AVA Control Software and Data Hub

Scaling up crystallisation: Insights from CatSci and BlazeMetrics

In this technical webinar our hosts discuss the importance of developing a good crystallisation process for APIs, and how process analytical technologies (PAT) can enhance understanding of the process.

Dr Scott shows case studies designing the crystallisation processes of two compounds, to determine the most stable form for further process development.

Dr Callahan explains how advanced technologies, such as the Blaze probe increase process understanding which can mitigate risks during process development and help optimise crystallisation processes.

Webinar: How to optimise mixing within your jacketed reaction vessels

In this webinar we will discuss factors to consider which apply when scaling chemical reactions up or scaling down to predict or reproduce conditions observed in the larger scale manufacturing environment.

15 min Webinar: Consistent Scaling Up

Scaling up chemical reactions can present a number of challenges with respect to efficient mixing, mass transfer, controlling exothermic reactions, heat transfer and reaction kinetics.

In this webinar we discussed some simple guidelines which apply when scaling chemical reactions up or scaling down to predict or reproduce conditions observed in the larger scale manufacturing environment.

Webinar: The benefits of Jacketed Lab Reactors and considerations when choosing a system

When purchasing a jacketed lab reactor setup for scaling up your process, there are many considerations to be made.

In this webinar we cover the fundamental points of specifying the right reactor and ancillary devices to ensure that you get the optimal performance of your jacketed lab reactor system for scale-up and process development.

Webinar: How to achieve efficient temperature control when using Jacketed Lab Reactors

When it comes to chemical reactions in both R&D and production processes, achieving the right temperature is crucial. In this webinar we will be joined by Dr Paddy Delaney from Huber to discuss the factors that influence temperature control when using jacketed lab reactors as well as advice on how to improve the performance of your system.

Accelerate your OPRD with Mya 4

Accelerate your Process Research and Development with a flexible reaction station. In this webinar we’ll show you how to improve reproducibility and eliminate time-wasted manually recording results with automated data logging.

Mya 4 can be set up quickly: benefitting from flexible and versatile configurations, easily meeting the needs of different applications and projects.