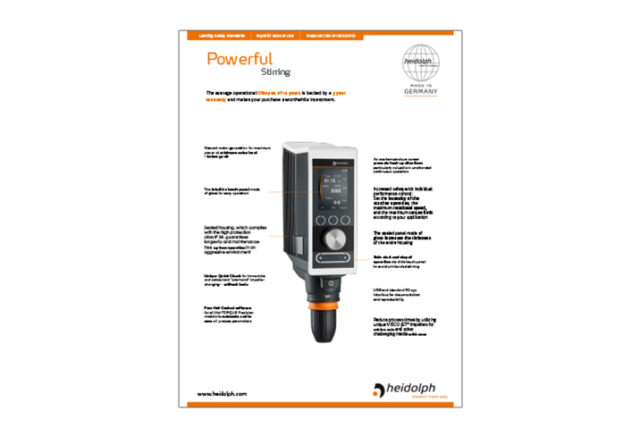

Hei-TORQUE Overhead Stirrers

The powerful Hei-TORQUE series can accomplish the most demanding mixing tasks whilst providing the highest safety and increased operating lifetime

Hei-TORQUE Core

The simple model from Heidolph, is lightweight and compact, designed for low to medium viscosity applications. Versatile with a timer function and boost button.

Hei-TORQUE Expert

Powerful stirring with simple handling. Easy to use and capable of handling volumes up to 100 L.

Hei-TORQUE Ultimate

The advanced model with a menu driven interface as well as RS232 and USB connectivity for connection to control software.

New Hei-Torque Core

The lightweight overhead stirrer for big tasks! The new Core model complements the Hei-Torque range of laboratory overhead stirrer series; providing an easy to use, entry level unit which has the same robustness and reliability from Heidolph.

Compact

The compact design of the new Hei-Torque Core allows its use in closed systems such as fume hoods, reactors and production systems

Lightweight

With a net weight of 2.3 kg it is lightweight yet powerful enough to handle a variety of basic stirring applications with a maximum performance of 40 Ncm torque

Hei-Torque Core

- The compact design allows for integration in closed systems, such as fume hoods, reactors, or production systems

- Suitable for low- to medium-viscosity media up to 25 l

- The large diameter of the chuck (10 mm) allows you to use even large impellers and VISCO JET® tools.

Hei-TORQUE Expert

Ideal for standard stirring tasks.

Stirrer with 100, 200 or 400 Ncm torque. Designed to mix and disperse media that require non-reproducible results in high-viscosity applications

Hei-TORQUE Expert

- Indication of torque output to monitor viscosity changes

- Digital 2.4” display for ease of operation

- Constant speed even under changing loads

- Safe start and stop of operation via slide touch panel to avoid unintended stirring

Hei-TORQUE Ultimate

Ideal for demanding tasks which require reproducible results or software control.

Stirrer with 100, 200 or 400 Ncm torque.

Menu driven interface with several options for individual settings such as ramps and interval operation.

USB and RS 232 interfaces for connection to computers.

Digital 3.2” display for ease of operation:

• Allows for pre-programmed profiles which can be saved

• Accurate torque indication shows any viscosity changes

• Watch rpm and torque graphs live

Hei-TORQUE Ultimate

All performance-related parameters can be set individually:

- Intensity of the start operation – from slow to fast

- The rotational speed can be limited to avoid splashing media

- The torque limit prevents damage to the impeller, e.g. when using fragile impellers in high viscous media

- Newest motor generation provides maximum power at minimum noise level

- Safe start and stop of operation via slide touch panel to avoid unintended stirring

Motor

Newest motor generation for maximum power at minimum noise level - below 50 db

Touch-panel

The intuitive touch-panel made of glass for easy operation

Sealed housing

Sealed housing which complies with the high protection class IP 54• Guarantees longevity and maintenance free 24-hour operation in an aggressive environment

Unique Quick-Chuck

Unique Quick-Chuck for immediate and convenient 'one-hand' impeller changing - without tools

Reduce process times

Reduce process times by utilizing unique VISCO JET® impellers for mixing gels and other challenging media with ease

Over temperature sensor

An over temperature sensor prevents heat-up situations particularly valuable in unattended continuous operation

Safe start and stop

Safe start and stop of operation via slide touch panel to avoid unintended stirring

Sealed panel

The sealed panel of glass increases the tightness of the entire housing

Increased safety

Increased safety with individual performance control: set the intensity of the starting operation, the maximum rotational speed and the maximum torque limit according to your application

USB and standard RS 232 interface

USB and standard RS 232 interface for documentation and reproducibility

Browse our range of products

For chemical synthesis, process development, evaporation and work-up

Hei-TORQUE Accessories

- Telescopic stand

- Clamp

- Flex coupling

- Flexible shaft

- Shaft guard

- Shaft guard adapter set

- Stand S2 XXL

- Universal stand S2

- Stirrer guide (NS 29/32 PTFE)

Stirrer Tools & Paddles

Range of impellers

Stirrer Tools & Paddles

- TR 20 Radial-Flow Impeller

- TR 21 Radial-Flow Impeller

- AR 19 Anchor-Type Impeller

- VISCO JET® – 60 mm

- VISCO JET® – 80 mm

- VISCO JET® – 80 mm (POM)

- VISCO JET® – 120 mm

- VISCO JET® – 120 mm (POM)

- VISCO JET® CRACK – 80 mm

- VISCO JET® CRACK – 120 mm

Browse the range

For chemical synthesis, process development, evaporation and work-up

Webinar: Optimising Mixing: Techniques for Better Reactions

The webinar will cover the importance of stirring and its impact on reaction rates, product quality, and efficient heat transfer. We will explore the benefits and limitations of magnetic stirring, how to select the right stirrer bar, and the use of evaluation kits.

Attendees will also learn about the advantages of overhead stirring for both small and large volumes, especially in viscous and heterogeneous reactions, and discover the impact of different impellers on mixing.

Insights into scaling up from laboratory to production scale and considerations for technology transfer will be shared. Additionally, we will compare high shear vs. low shear mixers, radial vs. axial flow impellers, and understand the importance of vessel geometry and baffling for optimal mixing.

Webinar: Benefits of overhead stirring on a small scale

Join us to discuss the benefits of overhead stirring on a small scale:

- Are you using magnetic or overhead stirring for small scale research and process development?

- What’s the difference and why does it matter?

- What factors can be affected when moving from magnetically stirred reactions to overhead and how might this help improve your chemical development and scale up?

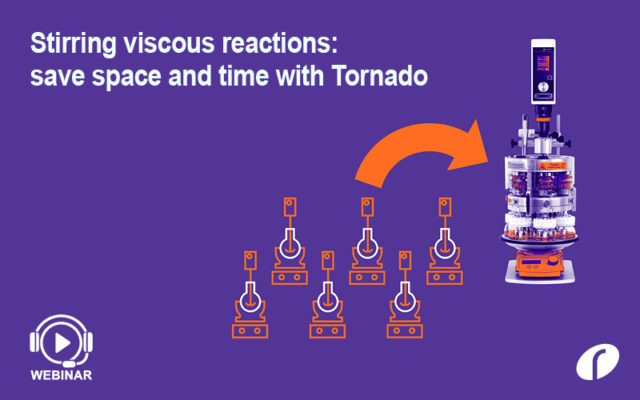

Webinar: Stirring viscous reactions - save space and time with Tornado

Do you require mechanical stirring on small scale reactions? E.g. viscous materials, heterogeneous mixtures, fragile solids?

Join us to see the Tornado Overhead Stirring System in action. Save time and space for the overhead stirring of multiple reactions in round bottom flasks.