Heat-On makes your chemistry safer, cleaner and faster

Replace messy oil baths, heating mantles and avoid spills. Heat-On accepts vials, tubes and flasks from 10 ml to 5 litres. Fits on all leading hotplate brands with a 145 mm Ø top plate; optional adapter plate for 135 mm Ø top plates

Unique well design eliminates cracking of flasks.

Blocks feature two probe holes for added convenience. Optional and detachable lifting handles. Optional PTFE Safety Covers reduce risk of user touching hot blocks.

Solid aluminium blocks provide even heating

Lightweight design allows rapid heating. Use up to 260˚C. For vials, tubes and flasks from 10 ml to 5 litres, plus option for Florentine (pear-shaped) flasks.

Choice of block finishes

Fluoropolymer coating gives superb chemical resistance. Anodised finish is durable, lower cost option.

Heat-On heats hotter, faster

Heat-up tests have shown Heat-On can boil a 250 ml flask of water in under 11 minutes, faster than an oil bath and faster than other blocks.

Safer

The risk of oil fires and injury from hot oil spills, plus the mess and cost associated with the use of oil means that oil baths no longer represent safe working practice in labs.

Cleaner

Heating mantles are expensive, difficult to clean, do not respond well to spills and often create hot spots when heating.

Greener

Scientists are increasingly turning to specially designed aluminium blocks located on stirring hotplates to heat standard round bottom flasks.

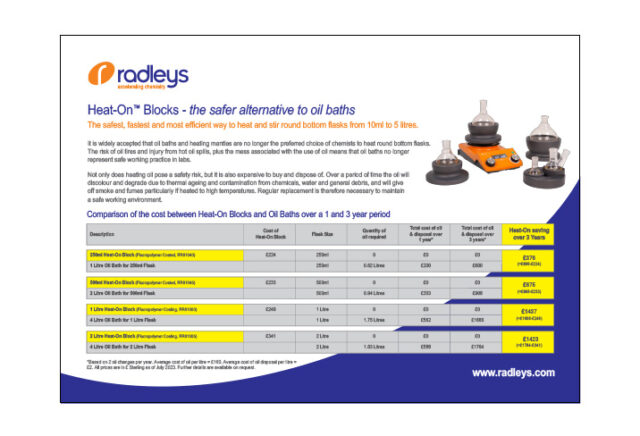

Oil baths are messy, dangerous and costly

- Oil will discolour and degrade with repeated heating and contamination from chemicals, water and general debris.

- Degradation results in a dangerous lowering of the oil’s flashpoint as well as increased smoking and fumes.

- Oil should be regularly replaced to maintain a safe working environment.

- Disposal of oil waste must be done in an environmentally and safe way, with associated costs.

For a comparison of the cost of using a Heat-On Blocks and Oil Baths over a 1 and 3 year period please see “Downloadable Resources” below to download the Heat-On V Oil Bath Comparison.

Lightweight design enables rapid safe heating

- Up to 260 °C. Uses 30% less energy. Heats water 66% faster

Unique well design prevents flask cracking

- Unlike many other inferior blocks, Heat-On will not crack your flask when cooling

Over 50 styles and sizes to choose from including Florentine flasks

- Accepts tubes and flasks. 1 ml to 5 litres

Heat-On Multi-well Block

- Accepts two 50 ml or 100 ml flasks, or one 150 ml flask

Fits all leading hotplate brands

- Suitable for a 145 mm ø top plates. Optional adapter for 135 mm ø top plates

PTFE safety covers reduce the risk of burns

- Reduces surface temp. by up to 50%. Reduces energy consumption by 15%. Available for the most popular Heat-On sizes

Fluoropolymer coating

- Superb chemical resistance. Easy to clean. Speeds up heating times

Two temperature probe holes

- Accept 3 mm ø probe

Anodised finish

- Heat-On blocks are also available with a lower cost anodised finish if preferred

Square hotplate adapter

- Allows Heat-On to sit on a square top plate up to 200 x 200 mm

Heat-On heats hotter, faster

Heat-up tests have shown Heat-On can boil a 250 ml flask of water in under 11 minutes, faster than an oil bath and faster than other blocks.

Not all block designs are the same

Another controlled test showed that a 2000 ml Heat-On block and flask, containing 1000 ml flask of water boiled 66% faster than the leading competitor.

Save energy and money

Heat-On is energy-efficient – using 30% less energy than the leading competitor, when boiling water over a 7 hour period

Heat-On Fluoropolymer Blocks

Fluoropolymer coating gives superb chemical resistance

These popular Heat-On blocks have an innovative fluoropolymer coating that:

- Offers outstanding chemical resistance to most solvents, acids and alkalis

- Extends the product life

- Is easy-to-clean

- Reduces heat-up time

Heat-On Anodised Blocks

Anodised Blocks

Heat-On blocks are available with a lower cost anodised finish if preferred.

- Offers good resistance to most common lab solvents

- durable hard anodised surface resists impact damage and is easy to clea

Heat-On Multi-well Fluoropolymer and Anodised Blocks

The Multi-well holder is designed to hold one or two inserts for flasks or tubes

- Inserts are available for 10 ml, 25 ml, 50 ml, 100 ml and 150 ml flasks

- Flask inserts also feature cut-away sides for use with two or three neck flasks

- Multi-tube inserts are available for 16 mm, 17 mm, 20 mm and 24 mm, 28 mm and 1 inch tubes or vials

- Multi-well holder suitable for 145 mm Ø top plates, with optional adapter plate for 135 mm Ø top plates

- Holder and inserts available with fluoropolymer coating or anodised finish

Heat-On Florentine Fluoropolymer Blocks

A range of blocks for Florentine (pear-shaped) flasks are available with a choice of a fluoropolymer coating or anodised finish.

Heat-On PTFE Safety Covers

Benefits

- Reduces the temperature of exposed surfaces by up to 50%

- PTFE insulation reduces energy consumption by 15%

- Chemically-resistant PTFE withstands temperatures up to 260 ˚C

- Prevent accidental spills of solvents on to hot surfaces

- Fits easily over existing Heat-On Blocks

- PTFE Covers for all popular Heat-On sizes

Improved safety

Manufactured from solid PTFE, these Safety Covers provide an insulating barrier between the user and the ‘hot’ Heat-On blocks. Tests show that the temperature difference between the outside surface of the PTFE cover and the Heat-On block can be as much as 100 °C reducing the temperature of exposed surfaces by as much as 50%.

Improved efficiency

The insulating properties of the PTFE Safety Covers mean that up to 15% less energy is required to maintain temperatures for extended periods.

For chemical synthesis, process development, evaporation and work-up

Webinar: Unleash your humble hotplate – it can do so much more than you think

Are you making the most of your hotplate?

Louisa Quegan and Keren Abecassis share their chemistry lab hacks: showing you a range of tools you might not know about.

From 1 position to 45 on a single hotplate – with working volumes between 0.5 ml and 2.5 L. Lou and Keren discuss their personal experience in the lab using traditional methods vs. this range of tools.

Webinar: Why you might be doing your small-scale process development wrong

Are you using round bottom flasks with heating only equipment for your small-scale process development chemistry? Do you find these experiments don’t scale up as well as you would like?

Let’s talk about what’s wrong with this traditional set up and what you can do to improve it.